Company

At a Glance

-

NET SALES 2020

900

MILLION USD

-

PSERSONNEL

500

EMPLOYEES

-

REGIONAL OFFICE

8

COUNTRIES

-

WARRANTY SERVICE

500+

SHIPS

-

> 3,500

SHIPS DELIVERED

BY HHI GROUP -

No.1

AFFILIATED WITH

HHI GROUP'S

SHIPBUILDERS -

> 240

ORDER BACKLOG

AS OF JUNE 2020 -

> 250

RETROFIT

CASES -

> 30,000

GROUP

EMPLOYEES -

> 200

MONITORING

SHIPS AT DIC*

* Digital Innovation Center

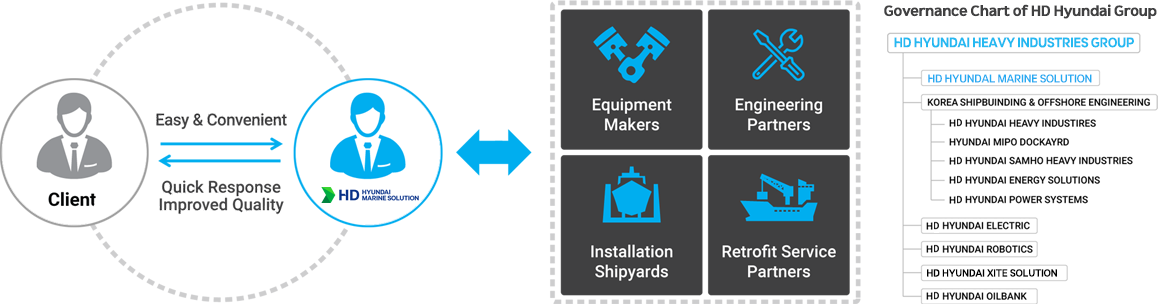

HD Hyundal Marine Solution (HMS) provides services for our clients so that the life of their ships, machinery and power plants can be extended by responding to constantly changing circumstances.

Our one-stop service center ensures that the Hyundai brand ships and products are repaired, optimized and upgraded to meet industry standards throughout their entire lifespan.

Clients can get access to all the technical support they need, such as genuine spare parts from the original equipment manufacturers (OEM), performance optimization for long-term efficiency and retrofits when necessary.

Business

| Marine |

|

|---|---|

| Power Plant | |

| Digital |

|

Strength

Your Most Reliable Business Partner

- Reliable service provider with proven and excellent project management capabilities across the marine service industry.

- Recognized as the "Most Reliable Partner" by our clients and customers by demonstrating ability to perform extended work scopes.

Customer-Oriented Service Provider

- Ready to respond to our customer's needs all over the world via One Single Contact Point 7/24/365 emcompassing retrofit, spare parts and digital technology.

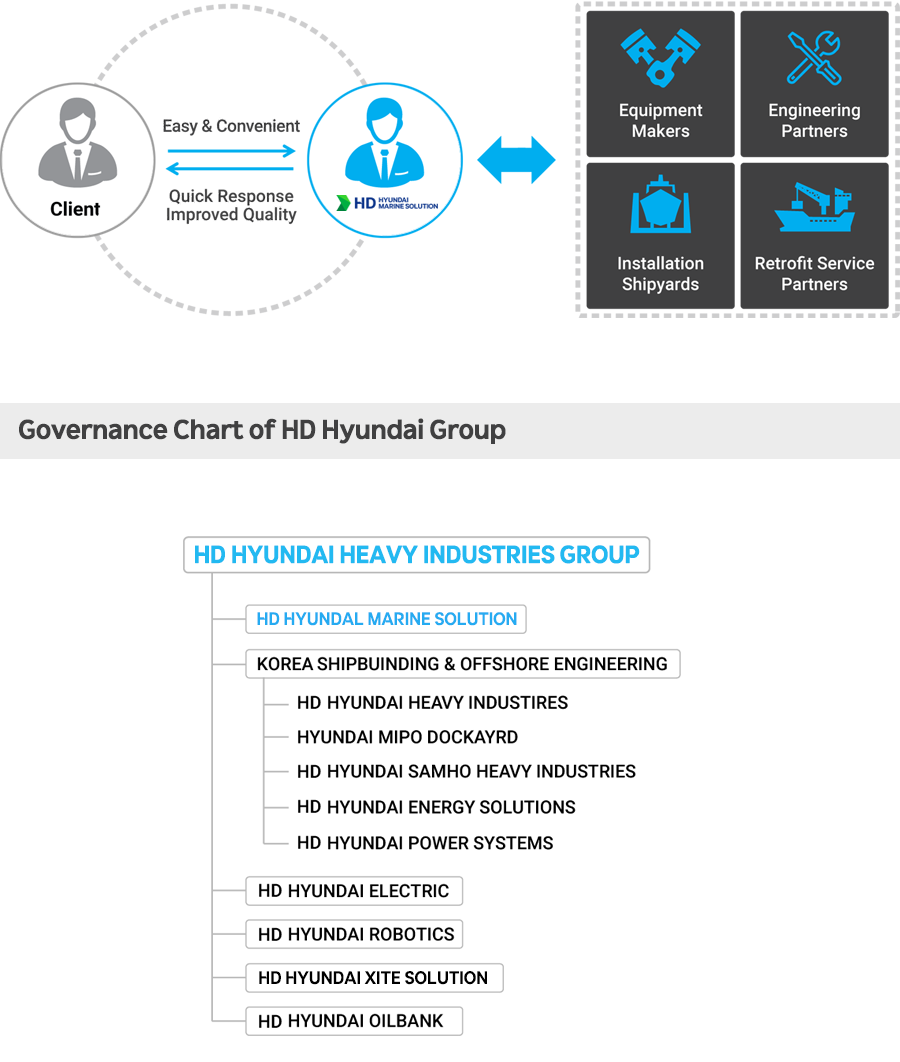

Our Service Solutions Coupled with HD Hyundai Group's Support

- Well aligned with supports in engineering, procurement, logistics and finance from HD Hyundai Group's shipbuilders who had deep expertise and rich history of experiences.